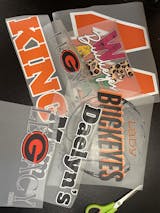

Dtf prints are prints transferred to more than one type of fabric. It takes its name from printing, since printing is transferred directly with technological devices. DTF prints transferred directly to the fabric surface are applied to many textile products and various decorative products. There are different colors and models as well as types of prints. Help is taken from designers to ensure that the designs prepared according to the surface to be printed have an aesthetic appearance. In specially prepared printing designs, various details such as color harmony, shapes and patterns, surface and printing color are determined correctly and the process of printing begins. During print transfer, print transfer is made to the surface using a heat press. Various prints are created thanks to many different types and colors of ink, depending on the materials used.

Scalability in DTF printing determines the aesthetic appearance and size of the print. An eye-catching print model is always preferred. It is possible to obtain many designs with DTF printing transferred to various textile fabrics. In design prints, the size of the design is important in terms of appearance. Appropriate scaling highlights the quality of the design. Prints prepared in the correct ratio provide the correct size thanks to appropriate scaling. The importance of scaling is the quality of the print and proper sizing. As a result of incorrect scaling, the shapes and details in the print on the fabric surface will not appear correctly. Products that are crooked or incorrectly scaled must be re-entered into the printing process.

The appearance and size of prints are important to customers and businesses. Adjusting complex patterned prints, shaped, written prints and colorful designs in the right ratio creates special prints that the manufacturer will design for the customer. Since the usage area of prints is diverse, the prints transferred to each fabric surface may not have the same properties as each other. Fabrics with different properties are obtained as a result of different printing materials and offered to buyers. Thus, working carefully for the appearance of the prints at every stage gives correct results.

The Importance of Sizing in Print Design

When specially preparing design prints, it is necessary to proceed by paying attention to the determined stages. The prints must go through a meticulous working process to ensure that the size is adjusted correctly and their dimensions are appropriate. Sizing in print design ensures that the prints of the products and the printed fabric surfaces appear neat and aesthetic. That's why proper scaling is important for every print. Thanks to the adjustment made in the size of the prints, the products are made suitable for sale. Prints that appeal to the eye and have an aesthetic appeal attract the attention of buyers. Faulty products made during printing go through re-printing stages while being sized and are detailed in each process until the quality control stage. In order to avoid incorrect scaling, a system is established and appropriate scaling is made depending on the system. DTF prints prepared with custom gang sheet are carefully examined until the last stage and the process ends with the packaging stage.

With the special preparation of the prints, the colors of the prints transferred to many fabric surfaces are as important as the sizing. In particular, a harmony must be ensured between the surface to be printed and the printing pattern colors. Because colors that match the color background show the print more clearly and provide an interesting appearance. Incompatible colors on the color background and pattern background create chaos. Therefore, the importance of colors is directly related to print sizing. If the colors and patterns of the prepared prints are digitally checked and then printing is started, the possibility of errors is minimized. Error-free prints satisfy the customer and make it suitable for cooperation with more businesses.